- #Gas lift pipesim correlations pdf

- #Gas lift pipesim correlations software

- #Gas lift pipesim correlations simulator

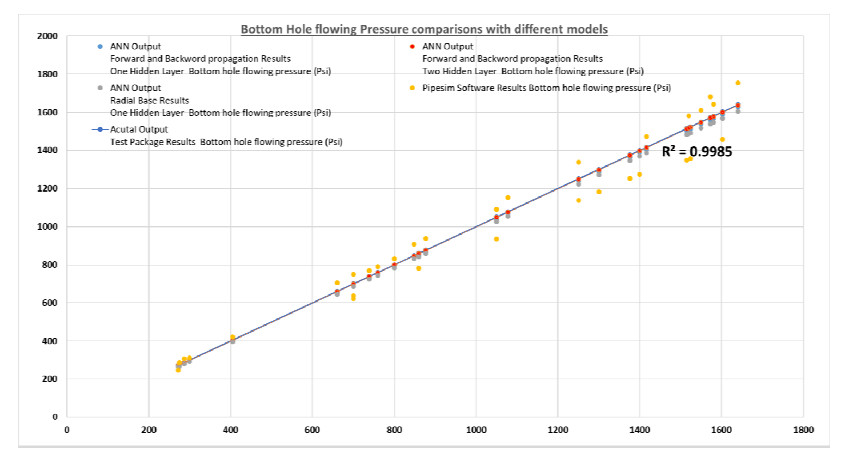

Heat selection modeling: Accurate prediction of heat transfer is critical in calculating the temperature of the desired fluid properties in the system, the formation of solids, and, in principle, for all global thermal design systems. PIPESIM performs energy balance calculations calculated for a variety of heat transfer mechanisms. You use individual PIPESIM modules for a wide range of analyses, including well modeling, nodal analysis, field planning, artificial lift optimization. were found to be the most convenient correlations for gas lift wells, then nodal analysis tool was used to give the optimum oil rate as in Figure 5.

#Gas lift pipesim correlations software

Liquid Characterization Modeling: PIPESIM provides two choices for the user, one is related to industry standard black oil concepts, and the other is a range of hybrid models of equation states. Depending on the application, users can choose from a wide range of features in the software to model a wide range of fluids. Multiphase Flow Modeling: PIPESIM employs a wide range of industry standard multiphase current communications as well as advanced three-phase mechanical models. This model makes it possible to calculate the flow structure, fluid latency, material motion characteristics, and pressure reduction of all stations along the production path. One of the biggest concerns of engineers is the safe design of wells and pipelines so that the produced fluids reach the process facilities safely and cost-effectively. The foundation of proper modeling of production systems is based on the following three main scientific areas, all of which are included in PIPESIM: In a word, with Schlumberger PIPESIM software, the correct amount needed to achieve the challenges of fluid flow and production optimization can be calculated.

#Gas lift pipesim correlations simulator

The PIPESIM simulator leverages a variety of fluid property correlations, multiphase flow correlations, and inflow performance relationships to generate an accurate description of your production systems. The PIPESIM simulator is used to model well performance, conduct nodal analysis, design artificial lift systems, model pipeline networks and facilities, and develop field production plans. The PIPESIM steady-state multiphase flow simulator enables the design and diagnostics of oil and gas production systems – from reservoir to processing facility. In the well gas lift design, Beggs & Brill Revised method is being selected for hydraulic calculation of pipeline flow due to low errors.Available versions: 2021.1, 2020.1, 2019.1, 2018.1, 2017.2

Consequently, due to increasing the volume of gas and connate water among the production after gas lifting, fundamental changes on the equipment, flow regimes and gas lift system are being proposed that production will be done by proper engineering method. Furthermore, the appropriate flow regimes through the well are being studied, and the most proper method for gas lifting and required surficial equipment will be designed for this field.

#Gas lift pipesim correlations pdf

For this purpose this web site is a repository for our works on correlations our papers on correlations are downloadable as PDF documents (preprints) from this site by. Therefore, 20 wells that their number starts A to T with this locations L280N, W115S and W002S are the candidates for gas lift procedures. Our overall goal is to create a 'tool box' of methods for generating and validating correlations, not only for gas-liquid and solid-liquid flows.

The purpose of this research is to design gas lift system in the oil wells of on the south fields of Iran by considering the maximum production connate water volume of 40 percent and average pressure drop (20–25 psia) throughout the year regarding production continuously or increasing the flow rate of the wells. The primary purposes in the gas lift design of a wellbore are to determine the proper depths and the location of valve installation, select appropriate flow regime during the pipeline and calibrate the pressures of the operating and unloading valves. Hence, the number of wells that used this method will continue to increase. Nowadays, most of the wells worldwide due to years of production and reducing the amount of energy which was supplied by natural drive mechanisms are being placed on artificial lift methodologies. This process was done by artificial patterns like a gas lift. The most common way to achieve an enormous production rate of a reservoir is to increase drawdown pressure during the production procedure by decreasing the bottom-hole pressure.

0 kommentar(er)

0 kommentar(er)